This is an important point often not fully explained. When we say connector loss, we really mean "connection" loss - the loss of a mated pair of connectors, expressed in "dB." Thus, testing connectors requires mating them to reference connectors which must be high quality connectors themselves to not adversely affect the measured loss when mated to an unknown connector.

The primary specification for connectors or splices is loss or the amount of light lost in the connection. Fortunately for both manufacturers and installers, only a few types of either are the ones used for most applications. There are only two types of splices but numerous ways of implementing them.

#COST TO SPLICE FIBER OPTIC CABLE INSTALL#

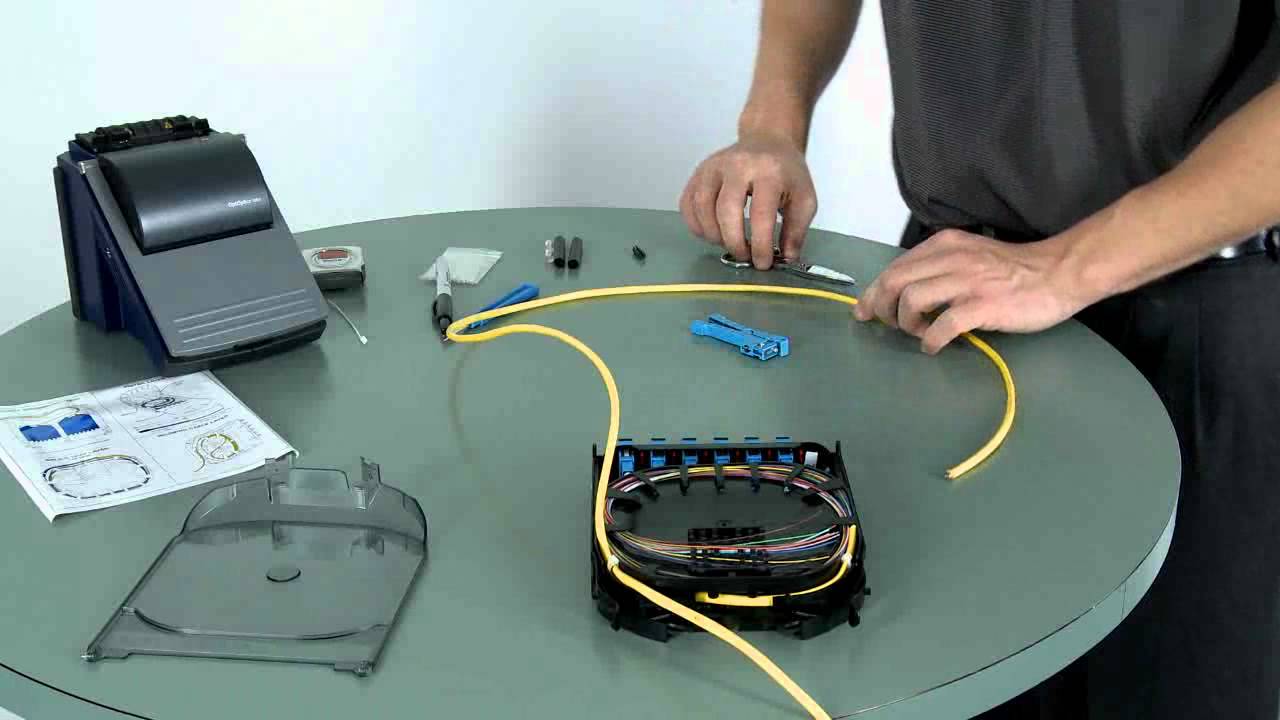

Manufacturers have come up with over 80 styles of connectors and about a dozen different ways to install them. Probably no fiber optic component has been given greater attention than connectors. Singlemode terminations require extreme care in assembly, especially polishing, to get good performance (low loss and reflectance), so they are usually done in a clean manufacturing facility using heat-cured epoxy and machine polishing. Most field singlemode terminations are made by splicing a factory-made pigtail onto the installed cable rather than terminating the fiber directly as is commonly done with multimode fiber.

Multimode fibers are relatively easy to terminate, so field termination is generally done by installing connectors directly on tight buffered fibers using the procedures outlined below. Different connectors and termination procedures are used for multimode and singlemode fibers.

#COST TO SPLICE FIBER OPTIC CABLE PATCH#

Mechanical splicing is used for temporary restoration and for most multimode splicing.Ĭonnectors are used for terminations, that is the ends of the fibers where they connect to equipment or to patch panels where fiber routing can be changed by patching different fibers together. Virtually all singlemode splices are fusion. Fusion splicing is most widely used as it provides for the lowest loss and least reflectance, as well as providing the most reliable joint. Splices are considered permanent joints and are used for joining most outside plant cables. Terminations must also be of the right style to be compatible to the equipment involved and be protected against the environment in which they are installed. Either joining method must have three primary characteristics for good optical performance: low loss, minimal reflectance and high mechanical strength. The FOA Reference For Fiber Optics - Outside Plant Fiber Optic Splicing and Terminationįiber Optic Connectors (L) and Splices in Splice Tray (R)įiber optic joints or terminations are made two ways: 1) splices which create a permanent joint between the two fibers or 2) connectors that mate two fibers to create a temporary joint and/or connect the fiber to a piece of network gear.

0 kommentar(er)

0 kommentar(er)